12 Ancient Tools Made From Unknown Materials

Here are 12 documented tools or tool-related materials whose true composition or manufacture only became clear after modern scientific analysis.

- Chris Graciano

- 7 min read

Archaeologists routinely recover tools whose appearance is familiar but whose actual materials, treatments, or manufacturing processes are puzzling until modern lab work reveals their secrets. In many cases the raw material looked like simple metal, resin, or ceramic under excavation conditions, but isotopic assays, metallography, gas chromatography–mass spectrometry, and other techniques later showed unexpected alloys, synthetic adhesives, meteorite iron, or chemical processes that ancient makers had mastered. These discoveries forced historians and scientists to rethink technological timelines, trade networks, and the sophistication of prehistoric and ancient craft traditions. These 12 cases below are all real. Each began as an “unknown material” mystery in the field and only became understandable after careful scientific analysis.

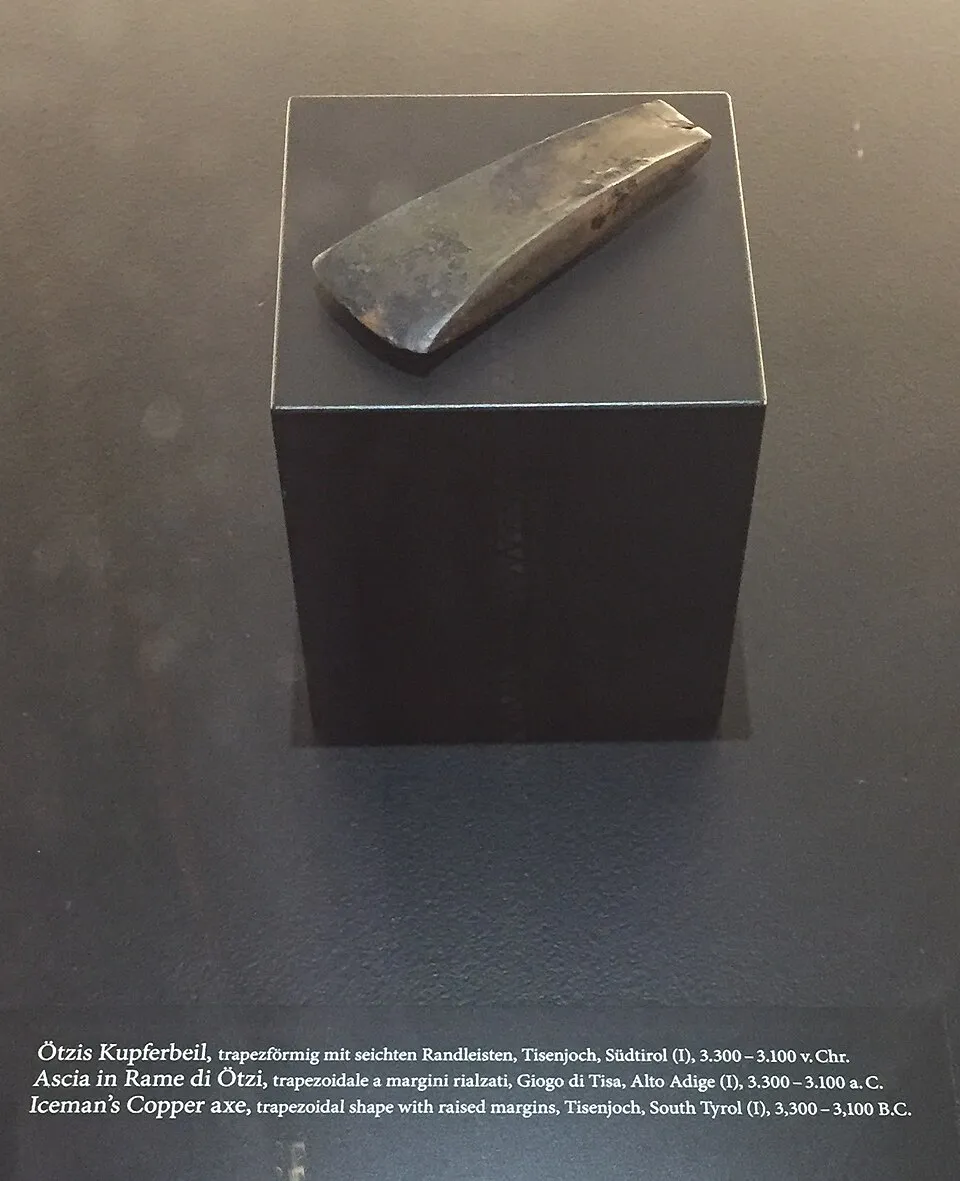

1. 1. Ötzi’s Copper Axe — Smelted Metal Earlier Than Expected

АлександрЛаптев on Wikimedia Commons

When Ötzi the Iceman was discovered in 1991, his axe looked like a normal tool. But tests showed the blade was made from smelted copper, not just a raw metal hammered into shape. This meant people in the Alps around 3300 BCE already knew how to heat ore, separate the metal from it, and pour it into molds. Scientists also traced the copper’s source, proving that Ötzi’s community took part in early trade networks. The axe changed ideas about when smelting reached Europe. It showed that metalworking was more advanced and widespread during the late Stone Age than many researchers once believed.

2. 2. Ötzi’s Birch Tar Adhesive — A Synthetic Organic Technology

Jorre on Wikimedia Commons

Another tool was discovered when Ötzi was uncovered. This time, the iceman carried tools held together with a dark, sticky glue. At first, researchers thought it was just natural tar, but chemical tests showed it was birch bark pitch. This pitch only forms when bark is heated in a controlled, low-oxygen environment. That means people 5,300 years ago understood how to create a man-made adhesive using careful heating methods. This finding proved that ancient toolmakers used real chemical processes, not just simple natural materials. It also pushed back the timeline for synthetic material production in Europe.

3. 3. Uluburun Cargo Alloys — Complex Bronze Compositions and Distant Tin Sources

Martin Bahmann on Wikimedia Commons

The Uluburun shipwreck contained pieces of copper and bronze that at first looked ordinary. Later tests showed the metals came from several different regions and included many alloy types, such as high-tin bronze and arsenical bronze. This means the ship carried goods from long trade routes that linked far-apart cultures. It also shows Bronze Age workers understood and learned how to mix metals to create different properties. These results changed the old belief that metalwork was mostly local and simple. Instead, the production of metal and trade were complex and connected across huge distances.

4. 4. Wootz/Crucible Steel — Carbon-Controlled Steel and Patterned Blades

Jlahorn on Wikimedia Commons

For years, people admired “Damascus steel” blades without knowing how they were made. Modern tests showed these famous swords were created from South Indian wootz steel, produced in closed crucibles that allowed smiths to control carbon levels. This process created tiny carbide patterns that gave the blades strength and beauty. Scientists studying the microstructure proved the steel was made with skill, not luck. The discovery showed that ancient metalworkers had advanced knowledge of heat, carbon control, and alloy behavior. It also placed early India at the center of high-quality steelmaking.

5. 5. Roman Marine Concrete — Pozzolana Chemistry That Strengthens in Seawater

Norbert Nagel on Wikimedia Commons

The ruins of the Roman harbor confused scientists because the concrete stayed strong for literally thousands of years. Later studies found that volcanic ash in the mix reacted with seawater to form tough minerals that actually grew over time. These reactions created a concrete that resisted cracks and chemical damage far better than many modern formulas. The discovery changed what experts believed about ancient building technology. It proved the Romans understood how to create long-lasting hydraulic concrete. What looked simple at first turned out to be one of history’s most impressive materials.

6. 6. Mesoamerican Rubber and the Lost Vulcanization Trick

Madman2001 on Wikimedia Commons

Ancient Mesoamerican rubber objects were once thought to be made from simple tree sap. Later studies showed that people mixed latex with plant juices from morning glory vines to change how the rubber behaved. This mixture made the material stronger, more elastic, and far more durable than natural latex alone. These changes prove the process was intentional and based on real knowledge of how different substances worked together. The discovery shows that ancient people practiced an early form of polymer chemistry long before modern rubber processing existed. It also reveals how creative and skilled these societies were in making materials for balls, tools, and everyday use.

7. 7. Tutankhamun’s Meteoric Iron Dagger — “Iron of the Sky” Proven by Nickel Content

Juhele_CZ on Wikimedia Commons

Tutankhamun’s dagger looked unusual because iron tools were extremely rare in Egypt at the time. When scientists tested the blade, they found high levels of nickel and cobalt, which are signs of meteoritic iron. This meant the metal literally came from a fallen meteor. Ancient smiths shaped the metal carefully, even though it would have been hard to work and very precious. Egyptians even referred to such metal as “iron of the sky,” showing they recognized its special origin. The dagger proves that people used rare natural resources with great skill, and it helps explain why iron objects from this period are almost never found.

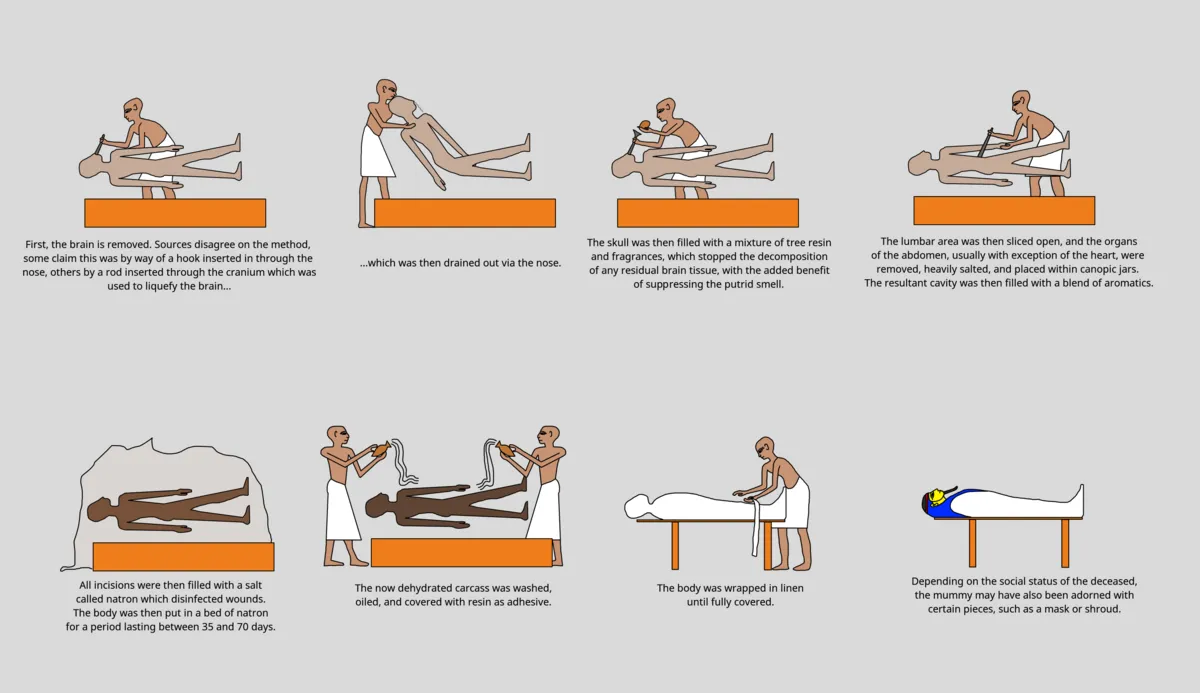

8. 8. Egyptian Mummification Resins — Complex, Imported Chemical Recipes

SimplisticReps on Wikimedia Commons

For a long time, the dark coating on mummies was thought to be a simple resin. Chemical tests later showed it was a blend of beeswax, pine resins, oils, bitumen, and sometimes imported fragrances. Each ingredient served a purpose, such as preventing decay, sealing the body, or masking smells. These recipes changed over time and between social classes, showing that embalmers experimented and refined their techniques. The ingredients also reveal trade connections, because some came from distant regions. What once looked like a single sticky substance turned out to be a complex, thoughtful mixture created to preserve bodies for thousands of years.

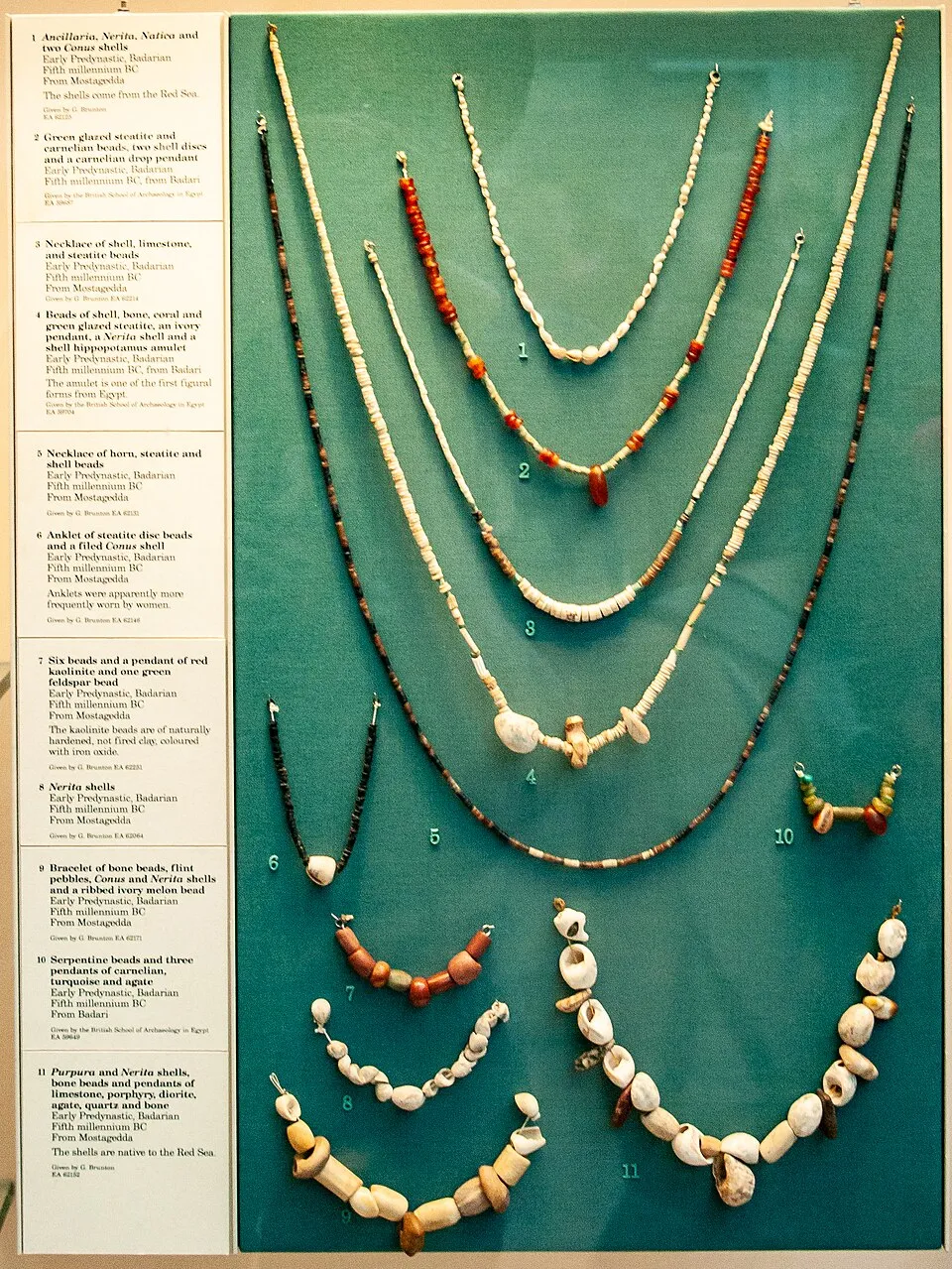

9. 9. Harappan Faience and Glazed Steatite Beads — High-Temperature Vitrification Recipes

British Museum on Wikimedia Commons

Beads from the Indus Valley civilization looked simple at first, but deeper study showed they were made with impressive technology. Craftspeople heated silica, minerals, and alkali materials in carefully controlled kilns to create a bright, glassy coating. This glaze stayed shiny and strong even after thousands of years underground. The process required choosing ingredients, managing heat, and understanding how materials changed when fired. These discoveries proved Harappan artisans had advanced skills long before similar methods appeared elsewhere. The beads reveal a level of planning and craftsmanship that early researchers did not expect from such an ancient society.

10. 10. Andean Arsenical Bronze Tools — Intentional Alloying for Improved Properties

Own work on Wikimedia Commons

Metal tools from the Andes often contained copper mixed with arsenic, and early researchers thought this happened by accident. Later tests showed the mix was deliberate. Andean metalworkers used ores that naturally contained arsenic, and they learned how to heat and shape them to create strong, hard tools. This allowed them to make high-quality metal items without relying on tin, which was harder to find in the region. The use of arsenical bronze shows they understood how to adjust metals to get better results. It also reveals a unique metallurgical tradition that developed independently from Old World methods.

11. 11. Han Dynasty “Magic Mirror” Bronze — Surface Microstructure Reveals Optical Trick

RawPixel

Chinese “magic mirrors” can project a hidden pattern onto a wall when sunlight reflects off them, even though the front surface looks smooth. For centuries, no one knew how this happened. Tests eventually showed that tiny differences in surface thickness and polishing caused light to scatter in special ways. These changes were intentionally created during casting and finishing, not accidental marks. The mirrors prove that ancient artisans understood how small physical details affected reflections. This discovery turned a mysterious effect into evidence of remarkable craftsmanship and early optical engineering.

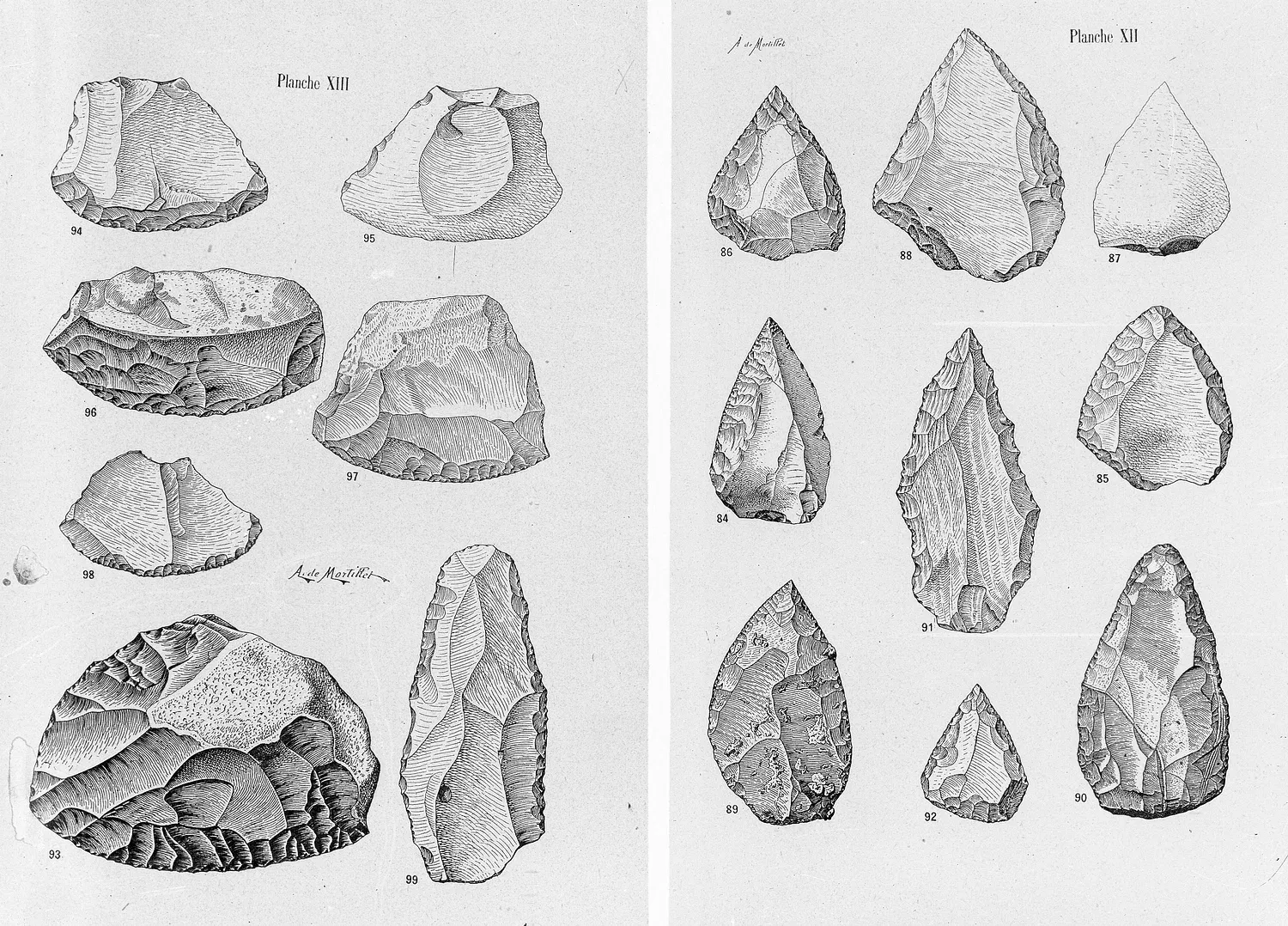

12. 12. Middle Paleolithic Hafting Adhesives — Complex Recipes in Deep Prehistory

Adrien de Mortillet and Gabriel de Mortillet on WorldHistory

Some Stone Age tools have traces of sticky material on them, and early scientists thought it came from natural tree sap. Modern tests showed something very different. The glue was made by mixing plant gum, resin, beeswax, and sometimes ochre, and it required heating and careful preparation. This means Neanderthals and early humans followed real recipes to make strong adhesives. They understood how heat and ingredients worked together to hold tool parts in place. This finding proves that complex chemical processes were used tens of thousands of years ago, long before written records or advanced technology.