20 Ancient Materials Stronger Than Modern Steel

Long before industrial furnaces and laboratories, ancient builders and blacksmiths created materials that modern scientists still struggle to replicate.

- Tricia Quitales

- 7 min read

Ancient civilizations were far more advanced in material science than many people realize. Their discoveries and crafting techniques produced substances of incredible strength, durability, and resilience that still amaze modern engineers. From legendary metals forged in secrecy to natural compounds that defy time, these materials often outperform today’s steel in toughness and longevity.

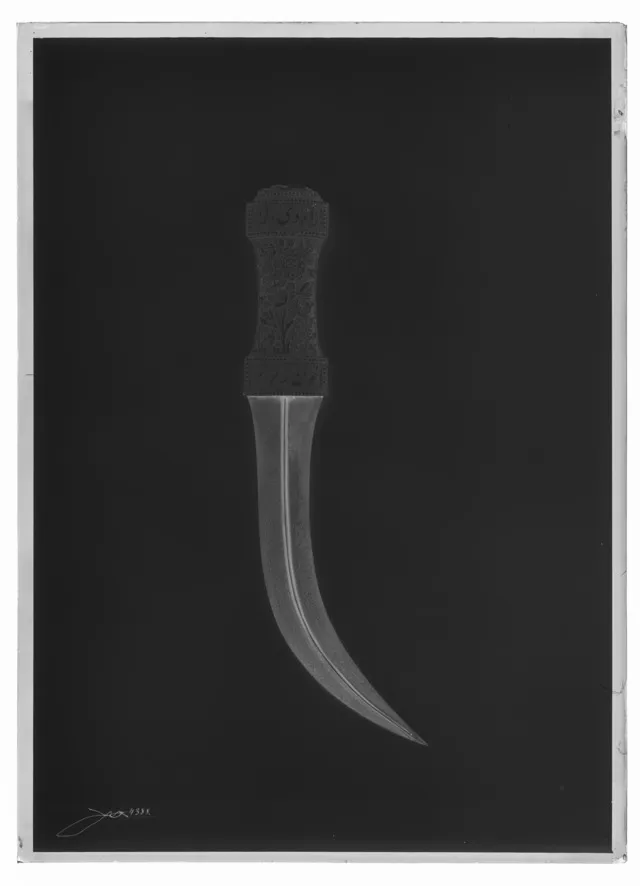

1. 1. Damascus Steel

Mxr on wikimedia

Famed for its wavy patterns and unmatched sharpness, Damascus steel originated in the Middle East. It could cut through weaker metals and retain its edge for years. Modern metallurgists have tried to recreate it but with limited success. The material contained carbon nanotube-like structures that gave it incredible strength. It remains one of history’s most mysterious metallurgical achievements.

2. 2. Roman Concrete

MM on wikimedia

Roman concrete, or opus caementicium, has survived for over two millennia. Unlike modern concrete, it becomes stronger with age due to its volcanic ash content. Seawater actually reinforces its structure rather than breaking it down. Engineers today study its composition to replicate its durability. The secret lies in the natural formation of resilient crystals within the mix.

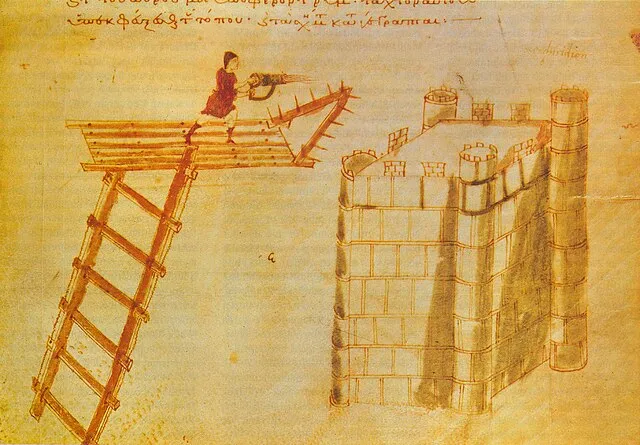

3. 3. Greek Fire Residue

Unknown author on wikimedia

Although mainly known as a weapon, the residue of Greek Fire produced a hardened substance that resisted corrosion. It adhered to surfaces with an almost metallic toughness. Scholars believe it contained lime, sulfur, and petroleum compounds that created a durable coating. Even in marine conditions, it proved remarkably resilient. Its composition remains one of Byzantium’s best-kept secrets.

4. 4. Wootz Steel

Unknown author on wikimedia

Originating from India, Wootz steel was the precursor to Damascus steel. It was known for its flexibility, strength, and ability to hold an exceptionally sharp edge. The carbon structures formed within it were similar to advanced alloys today. European swordsmiths admired and imported it for centuries. Its creation process remains a fascinating study of ancient metallurgy.

5. 5. Obsidian

Jstuby on wikimedia

A volcanic glass used by many ancient cultures, obsidian can be sharper than surgical steel. When fractured, it forms edges at the molecular level. Aztec and Mayan warriors crafted blades capable of slicing with unmatched precision. Scientists confirm that obsidian edges are far smoother than modern steel scalpels. Its natural perfection remains unmatched in cutting technology.

6. 6. Chinese Earthware Ceramics

Daderot on wikimedia

Ancient Chinese artisans developed ceramics with exceptional density and resistance to heat. Their porcelain and stoneware compositions were so refined that they rivaled metal in strength. Some high-fired pieces could withstand pressures similar to tempered steel. The secret lay in precise firing techniques and natural mineral blends. These creations show early mastery of thermal engineering.

7. 7. Egyptian Blue Pigment

Creative Commons Zero, Public Domain Dedication on wikimedia

Beyond its vivid color, Egyptian Blue formed crystals so stable that they still retain brightness today. The pigment’s molecular structure resists decay and heat better than many synthetic compounds. Researchers found it emits infrared radiation, revealing advanced chemical understanding. Its resilience has influenced modern nanotechnology. Ancient artisans unknowingly created one of the toughest pigments in history.

8. 8. Japanese Katana Steel

Creative Commons Zero, Public Domain Dedication on wikimedia

Forged through repetitive folding, Katana steel achieved molecular uniformity and strength. The technique removed impurities and distributed carbon evenly. Samurai blades could cut through metal armor without chipping. The process required immense precision and patience. Even today, metallurgists admire its balance of hardness and flexibility.

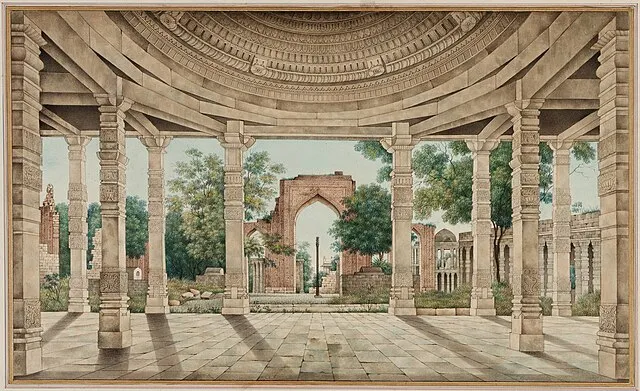

9. 9. Iron Pillar of Delhi

Unknown author on wikimedia

Standing for over 1,600 years, the Iron Pillar of Delhi has resisted rust almost entirely. Its surface forms a protective film of iron hydrogen phosphate. Modern scientists struggle to reproduce this level of corrosion resistance. The metal’s purity and precise forging method contributed to its longevity. It remains one of the most enduring examples of ancient metallurgy.

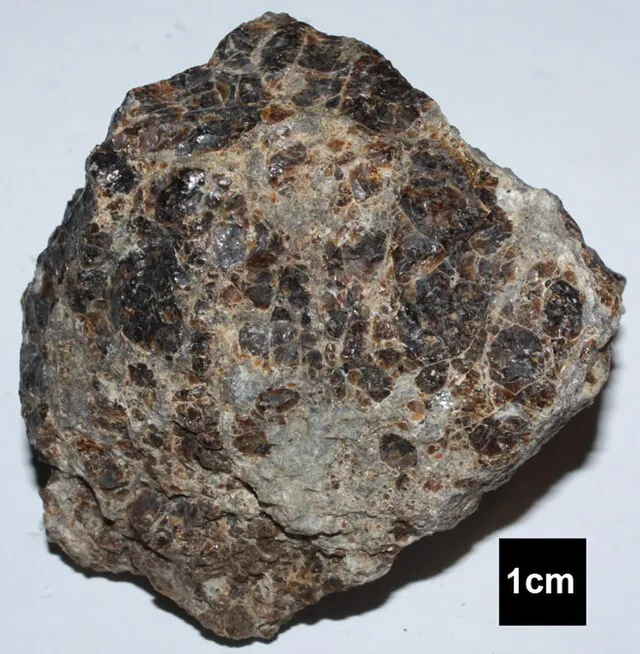

10. 10. Mayan Concrete

Titus Tscharntke on wikimedia

Mayan builders developed a type of limestone concrete that has survived in tropical environments. Its structure resists erosion and moisture far better than modern cement. The secret ingredient was a plant extract mixed with burned limestone. This created a self-healing effect when exposed to rain. Many ancient Mayan structures still stand firm because of it.

11. 11. Chinese Cast Iron

Fumikas Sagisavas on wikimedia

China was producing cast iron long before Europe discovered the technique. The metal’s carbon content made it incredibly hard and durable. It was used in bridges, weapons, and farming tools that lasted for centuries. The precise temperature control during smelting ensured strength and stability. Early Chinese metallurgy remains one of the most advanced in history.

12. 12. Viking Ulfberht Swords

Лапоть on wikimedia

These legendary Viking swords were made from high-quality crucible steel. Their carbon distribution matched that of modern steel, centuries ahead of their time. Ulfberht blades were nearly unbreakable and retained sharpness through countless battles. The secret method of refining the metal was lost for generations. Archaeologists regard them as technological marvels of the medieval world.

13. 13. Terracotta Army Coating

Gary Todd on wikimedia

The protective coating on the Terracotta Warriors of China has endured for over 2,000 years. Researchers found it contained unique lacquer compounds that resisted degradation. Its combination of natural resins and minerals created exceptional surface strength. The figures remain remarkably intact despite centuries underground. This durability shows the sophistication of ancient chemical engineering.

14. 14. Celtic Bronze Alloy

Creative Commons Zero, Public Domain Dedication on wikimedia

Celtic blacksmiths created bronze alloys with an impressive strength-to-weight ratio. Their precise mixture of copper and tin produced weapons that resisted corrosion. These alloys often outperformed early iron tools in flexibility and longevity. The metallurgical knowledge required was exceptional for its time. Modern bronze compositions still draw from these ancient principles.

15. 15. Persian Crucible Steel

Carpenter Steel Company on wikimedia

Persian metalworkers refined crucible steel to achieve both sharpness and endurance. Their process involved melting iron with plant matter to introduce carbon. The result was a pure and resilient alloy ideal for blades and tools. Its microstructure displayed intricate patterns similar to Damascus steel. Historians credit Persia as a vital link in steel development.

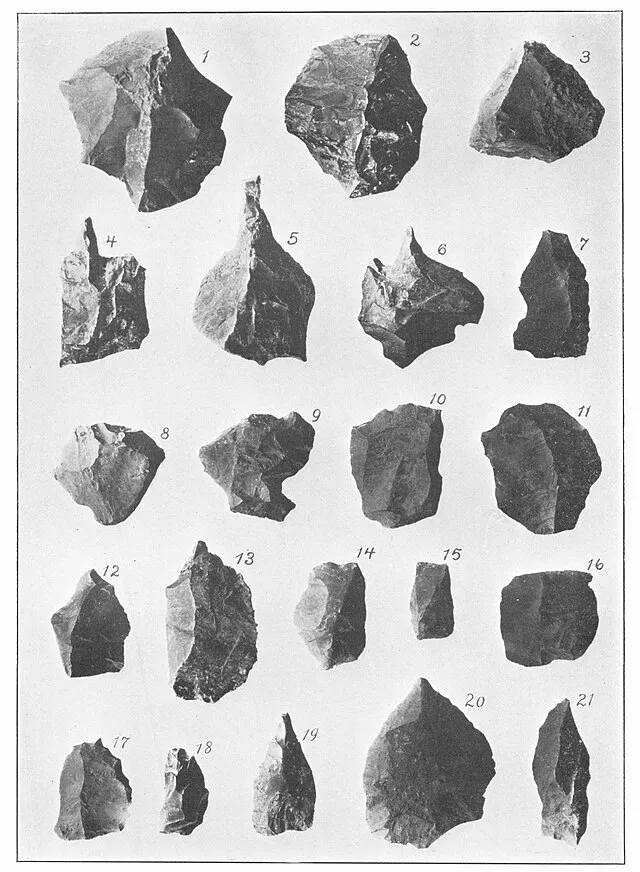

16. 16. Native American Chert Tools

Max Uhle on wikimedia

Chert, a form of flint, was used by Native Americans for arrowheads and blades. When struck correctly, it formed edges sharper than most modern steel knives. Its strength came from tightly packed silica crystals. Archaeologists still find chert tools in excellent condition today. It demonstrates nature’s ability to produce superior materials with minimal alteration.

17. 17. Ancient Greek Bronze Armor

Gary Todd on wikimedia

Greek bronze armor combined protective strength with lightness for mobility in battle. The alloy balance created an ideal mix of hardness and flexibility. Many recovered helmets and breastplates remain structurally sound after millennia. The consistent craftsmanship reveals advanced smelting control. Their durability still inspires modern alloy design.

18. 18. Chinese Jade

Gary Todd on wikimedia

Highly prized for both beauty and toughness, jade was used for weapons, tools, and ornaments. Its fibrous structure made it nearly unbreakable under pressure. Craftsmen shaped it with incredible precision using early abrasives. The stone’s resilience rivals that of advanced ceramics. Jade symbolized strength both physically and spiritually in ancient China.

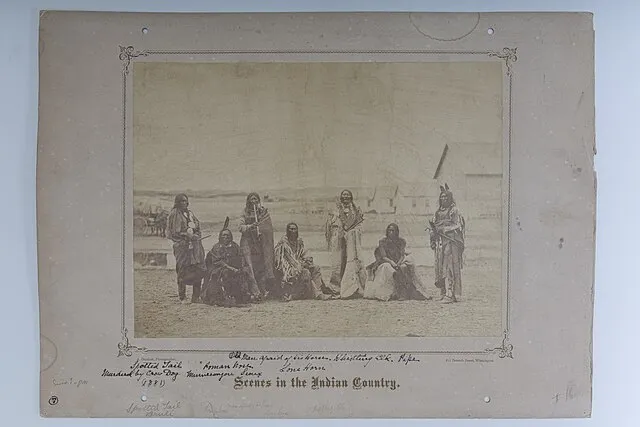

19. 19. Roman Lead Pipes

Alexander Gardner on wikimedia

Though lead is toxic, Roman pipes have remained structurally stable for thousands of years. The mineral coatings inside them prevented corrosion and cracking. This natural reaction created layers of protective carbonate crystals. The engineering of their plumbing system was unmatched in its era. Their durability highlights how even soft metals can achieve lasting strength through chemistry.

20. 20. Inuit Whale Bone Tools

Szilas on wikimedia

Arctic peoples crafted tools and weapons from whale bone with remarkable resilience. The natural composite structure of the bone provided flexibility and toughness. Even in extreme cold, these tools maintained integrity without splintering. The craftsmanship optimized the natural grain for maximum endurance. Their adaptive engineering reflected a deep understanding of material science.